Spoke & Hub Distributed Production

Maverick Synfuels > Oasis Methanol Plants > Spoke & Hub Distributed Production

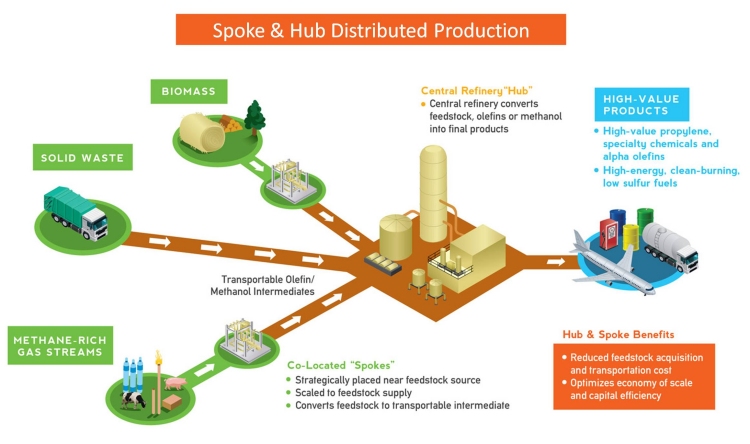

Maverick’s plants are designed to be both modular and scalable to local feedstock supply and economics. Our “Spoke and Hub” logistics model and transportable intermediates enable Maverick to engage in “feedstock arbitrage,” allowing Maverick to take advantage of imbalances in feedstock supply and demand to drive down the cost of feedstock for our processes. The Maverick “Spoke and Hub” distributed production model eliminates feedstock price fluctuations, reduces capital requirements, and minimizes technical and financial risk.

How Spoke & Hub Distributed Production Works

1. Feedstocks – Maverick plants are feedstock-flexible, and can accept biomass, municipal solid waste (MSW), and methane-rich gas streams.

2. Spokes – Smaller distributed ‘Spoke’ feeder plants are located and scaled based on the availability of smaller quantities of low-cost, non-commoditized feedstock supply. This approach eliminates the demand pressures on feedstock supply and keeps the feedstock costs low.

3. Conversion – The spoke plant converts the feedstock into synthetic gas (syngas).

4. Transportable Intermediates – The syngas is then converted into a transportable intermediate in the form of methanol or olefins, which are more economical to transport than raw feedstock.

5. Hub – The intermediate is transported to a larger centralized “Hub” plant. The Hub plant is scaled based on the intermediate supply and production economics.

6. Conversion – At the hub plant, methanol is converted to olefins using a methanol-to-olefins (MTO) process. The olefins are then converted into final products such as diesel, jet fuel, and propylene.

7. Distribution – End products are made available through the existing regional market and distribution infrastructure.